Top Tips for Maintaining Your Electric Motor

Top Tips for Maintaining Your Electric Motor

Electric motors are a standard piece of power equipment utilized across many industries for numerous uses, including wastewater treatment, fresh water distribution, agriculture, and basically any pumping application. They are essential for efficient operations to power pumps, blowers, industrial equipment, machine tools, and much more. Without them, you wouldn’t be able to deliver the timely service that customers have come to expect from your business.

However, electric motors are generally used every day, so they are subjected to much wear and tear over time. Without routine maintenance, your motors will deteriorate quickly and require a repair or even a full replacement much sooner than intended. This could lead to unexpected downtime for your business, adversely impacting your bottom line as you’re forced to halt operations until your motors are working again. You will need to pay for any necessary repairs, which also increases your operational expenses. It is crucial to keep up with maintenance tasks to prevent a costly breakdown.

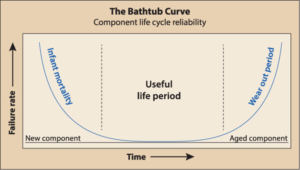

The life cycle of an electric motor follows the Bathtub Curve. Building your own motor maintenance program is the key to maximizing the useful life of your electric motor.

Motors have a lot of complex parts and components that should only be handled by a professional. If you attempt maintenance or repairs on your own, you could cause further damage to the equipment that could be even more expensive to resolve. Certified technicians will have the proper experience and training to maintain your electric motors and safely perform any repairs in a timely manner.

When it comes to maintenance, there are various tasks that your technician will handle. We’ll review some of the most common ones below.

Lubricate Bearings

Bearings are an essential component of a motor. They support the rotor to allow it to spin on its axis, which ultimately transmits mechanical power. Bearings must be properly lubricated to reduce friction between moving parts. Without enough lubrication, parts will wear out more quickly and could cause irreparable damage and shorten the useful life of

Over-lubrication of your motor bearings creates a big mess and may lead to premature failure if the excess lubricant works its way into the motor windings.

your equipment. Bearings should be treated with the specific type of lubricant that’s recommended by the manufacturer. Using the wrong kind can cause problems for your motor, so following the manufacturer’s instructions is best. You will also need to ensure that this task is completed at regular intervals to keep your bearings in prime condition.

It’s also important not to over or under-lubricate bearings, which can result in other issues for your motor. Your technician will know which kind of lubricant is appropriate for your bearings and how much to use. They will handle the task meticulously to ensure your motor has the protection it needs to operate reliably.

Clean and Inspect the Motor

It’s imperative to clean motors regularly to keep dirt, dust, and debris at bay. Motors will naturally accumulate these on their surface during normal operation. However, if your motors aren’t cleaned in a timely fashion, you may notice a decline in overall performance. Between your maintenance visits, you can wipe your motors down with a soft cloth, but you should never clean them with water or chemicals. Moisture exposure can cause rust and corrosion, which can extremely damage the equipment, even beyond repair.

It’s imperative to clean motors regularly to keep dirt, dust, and debris at bay. Motors will naturally accumulate these on their surface during normal operation. However, if your motors aren’t cleaned in a timely fashion, you may notice a decline in overall performance. Between your maintenance visits, you can wipe your motors down with a soft cloth, but you should never clean them with water or chemicals. Moisture exposure can cause rust and corrosion, which can extremely damage the equipment, even beyond repair.

It’s best to allow a technician to handle any major cleaning tasks for your electric motors. They will know which tools and techniques to use to clean motors thoroughly.

They can also perform a thorough inspection to look for any repair needs. Repairs should be made as soon as possible to minimize damage.

Reduce Vibrations

It’s normal for electric motors to have some minor vibrations. However, if you notice that one of your motors is vibrating excessively, you should shut it off and have a technician

Proper alignment is crucial in eliminating excessive vibration.

check it out as soon as possible. Left unaddressed, extreme vibrations can significantly damage the motor. Vibrations can be caused by misalignment, an unbalanced rotor, faulty gears, a worn bearing, and other issues that can be hard to detect on your own. A professional technician will be able to find the source of the vibration and provide an effective solution to reduce or eliminate harmful vibrations.

Replace Brushes

Some electric motors come with brushes that are responsible for transferring current to the rotor. When these begin to wear down, they become less effective at their job, which can negatively impact motor performance. Your technician will inspect these brushes at every maintenance check and replace them as needed.

Tighten Electrical Connections

Loose connections can cause performance issues for your motors. Your technician will look for any loose screws or terminals and tighten them securely. This is best done by a professional to prevent any electrical mishaps and to ensure that all connections are accounted for.

Test Operation

Your technician will also check the operation of your motors to ensure reliable performance. They will conduct a number of assessments, including checking voltage, current, insulation resistance, windings, temperature fluctuations, operational speed, and much more. With a comprehensive assessment of your motors, we can uncover any issues that would soon result in motor failure. This allows you to be more proactive about repairs. You can have them completed before they have a chance to damage your motor significantly. This will maximize your investment while keeping your operations up and running.

Benefits of Timely Electric Motor Maintenance

You need reliable electric motors to keep your business running efficiently. Routine maintenance is the best way to prevent major issues that can lead to motor failure. You don’t want to worry about unexpected downtime or lost productivity while waiting for a repair. With regular maintenance, you can reduce the frequency of repairs and keep your operations running smoothly.

Here are some of the top benefits of scheduling preventative electric motor maintenance:

- Energy-efficient operations:

Well-maintained motors will simply use less energy than poorly maintained ones. This makes them much more efficient to run, which will ultimately save you money on power bills.

- Longer motor lifespan:

Electric motors can last 15 years or more with proper maintenance. Keeping up with your maintenance schedule is the best way to maximize your motor’s lifespan so that you don’t have to pay for a replacement any sooner than necessary.

- Workplace safety:

A malfunctioning motor can cause a safety hazard for employees. Regular maintenance and timely repairs can reduce the risks of workplace accidents.

- Reliability:

Maintenance can help you uncover any issues that could interrupt your operations. You’ll be able to address them before they have a chance to disrupt your business.

- Cost savings:

You will be less likely to need major repairs or a complete motor replacement by addressing repairs promptly. This can result in significant cost savings for your company.

Valley Power Systems — Serving Your Power Needs Since 1949

Valley Power Systems is an authorized dealer for U.S. Motors, the nation’s largest manufacturer of electric motors and related components. Electric motors are available in many sizes, and our knowledgeable staff can help you choose the right ones for your applications. We understand that well-functioning electric motors are essential to your operations. Whether you need a new motor, maintenance, or repair, we’ve got you covered. Our company has been providing power solutions since 1949, and we look forward to many more years partnering with California businesses. Our goal is to keep your operations up and running with the right power products and services.

Contact Valley Power Systems today to learn more about electric motor maintenance.